WindFire Designs Paraglider Repair Service |

|

|

|

What we do

We are an arts and fabrication studio, which you can see at our main WindFire Designs site, or our studio blog. And we are a full service for all sorts of fabric wing repairs. We have been making our living repairing traction kites since the demand for that first started.

We offer to paraglider pilots the same high-quality and personal service that has made us such a benchmark for kite and soft wing repair.

|

Who we are

WindFire Designs was founded by Tim Elverston [me]. I grew up knowing that I must make things to stay sane. I have designed and built high-performance kites and ram-air foils, like the one above, for almost 20 years now. I adore sewing, and I am the lead on quality and technique for all the repairs here. There are two of us that sew. Myself, and Ruth Whiting. She is an artist, is my awesome wife, and she learned to sew and build kites here.

|

| |

|

| |

|

| |

Paraglider repair service by WindFire Designs

Structural integrity is directly related to precision and care. We thrive on details and we know soft wings inside and out.

Look to this link for our kite repair service pages. And here for blog posts about paragliders that come through our repair shop.

-

Many repairs are done internally without much visual evidence.

-

Yes, we can repair, fabricate, and replace bridle tension system lines.

Yes, we offer porosity testing for paragliders and fabric -

We repair nearly anything fabric, including harnesses and bags.

|

| |

Our quality

-

-

OEM fabrics, needle sizes, threads and stitching.

-

UV resistant cloth that will never gather dirt at the margins.

-

Rapid and personal service with almost 20 years experience.

-

Mostly internal patching to preserve all color and graphics.

-

All reconstruction is dynamically stretch-compliant with the structure of your wing—never too stiff, but slightly stronger.

-

Good-will and customer-oriented pricing and payment policies.

-

We love what we do each and every day.

We guarantee everything we do

What we do is our life. In the case of paraglider repair, it's also yours. We guarantee every last millimeter of our work.

|

How to get your paraglider repaired

- Give us a call if you like. My phone is in my pocket most of the time. 352 219 4269 Tim.

- It's also a great idea to email us initially. All advice is free and all our repairs are guaranteed forever. Having your email in our system is handy when the repair is complete.

- Print or fake our paraglider repair ticket. Please pack the ticket into the box with your wing.

- Pack your paraglider in a smallish box that you trust to make it here and back home to you. Leave out gear that is not in need of repair.

- Send it to the address on our contact page.

- We'll email you as we begin work on your wing.

- Don't hesitate to ask for strange things. We pride ourselves on versatility.

How long will it take?

Turn around time should be within about one week. We can get busy, usually when conditions are best for flying. However, we do not charge extra for rush repairs. But we do ask that you only request rush if you really need it.

How much does it cost?

Our high skill level and low overhead keep our prices very reasonable. We charge only by the hour and the average cost for paragliders is between $35 and $340. We like hearing that our prices are awesome, so we keep them that way.

|

|

|

Above is a Mac Para Eden 3 28 meter wing we repaired for Brian Haupt. Thanks Brian! You can see our repair on the port side of the wing. This complex damage was caused by a bridle line getting caught in the motor. Inside was major damage to the ribs and dribs and tow points, and the outside needed coverage because it had become fuzzy. It's dimensionally perfect. You can read about the process in this blog post.

|

| |

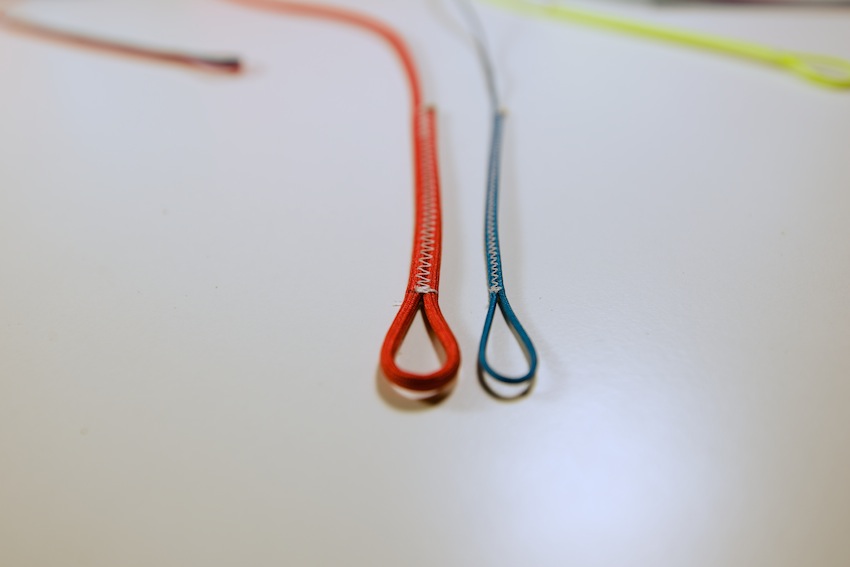

We rebuild damaged paraglider tension systems |

| |

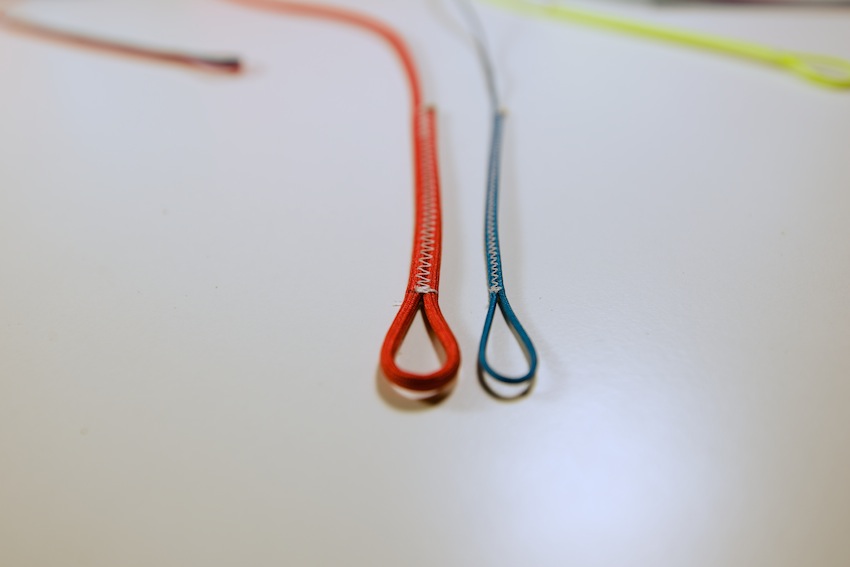

We repair and replace any and all paraglider bridles and lines. We match loop dimensions, stitch patterns, materials, and overall lengths within 1-2mm. We will also make lines to your spec upon request. Many customers prefer to send in the entire wing, and let us handle the job of fabricating and installing the new paraglider lines. However, if only one or two lines are damaged, and you want to install them yourself, just photograph your loops next to a metric ruler and send us that along with the other specs for the lines you'd like us to make.

We use OEM line specific to paragliding manufactured in Germany. Tedlar, Spectra, Dyneema, and Kevlar cores with and without Dacron jacket. Normally we can match color closely, if not perfectly. Often our line is slightly better than the original material. Many customers have damage on one side but not the other since often the prop will snag only a few lines. Sometimes it's reccomended to replace lines in pairs (both the bad lines and their mirror opposites), but normally it's not necessary. We have a lot of different lines available for the repair of paraglider tension systems, many more than in the below images.

|

|

|

|

| |

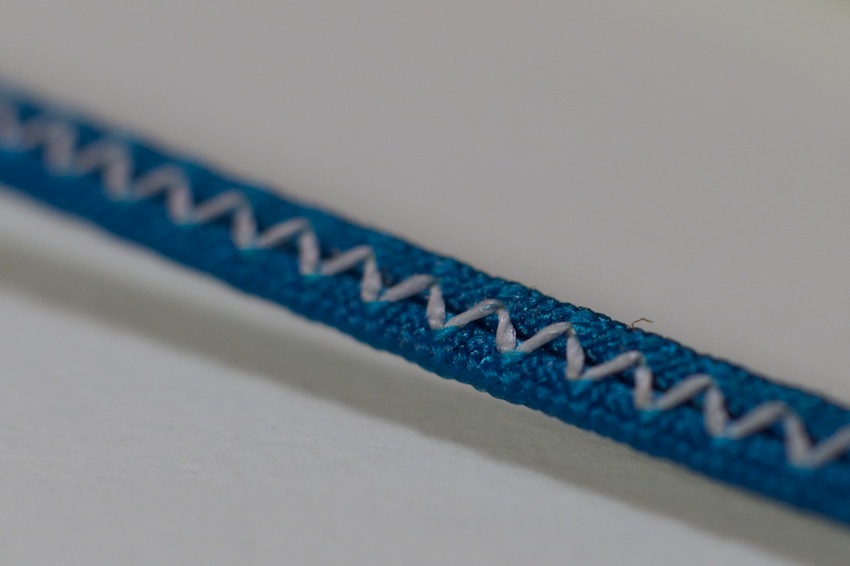

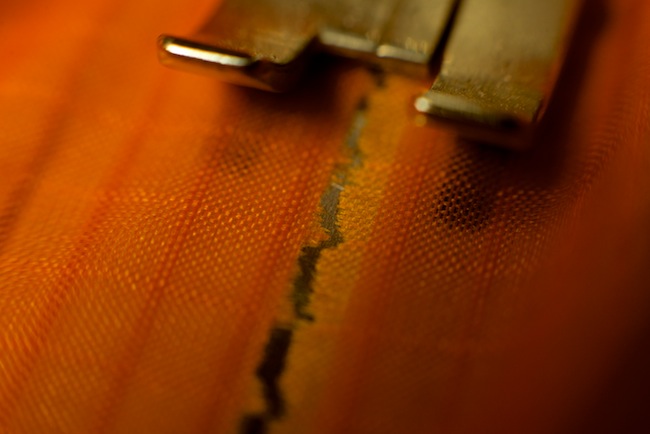

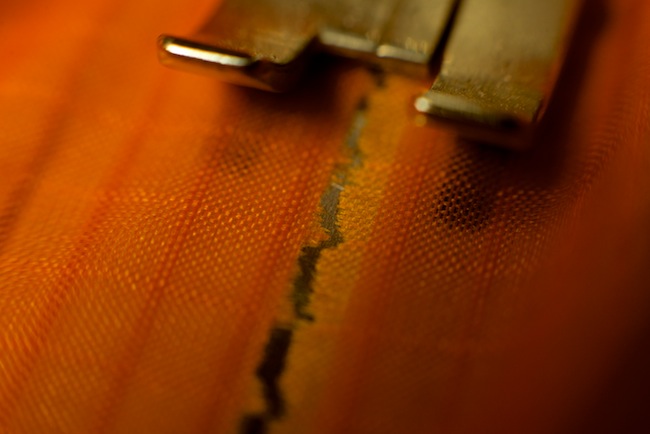

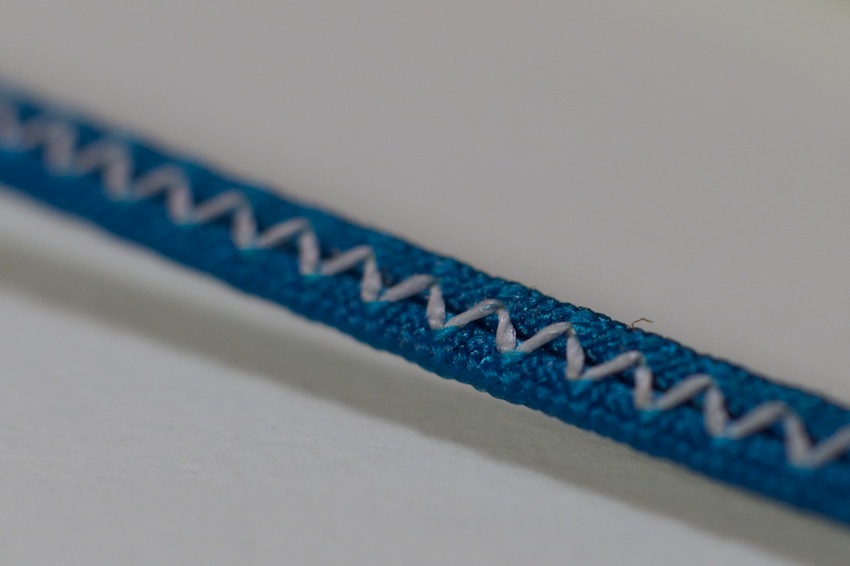

Below is a U-Turn Obsession I 2007 paraglider that was damaged during launch. This one was able to have the work done all on the interior. We use the triple-step stitch on this reconstruction because it is actually stronger than a straight stitch in this instance.

Check out a little more about another repair like this one at this blog post.

|

|

|

On Jan 26, 2010, at 3:27 PM, Doug Hannam wrote:

Aloha Tim,

I have received the wing. It looks great! Awesome job!

Look me up the next time you are in Oahu.

Thanks again for your great service, I really appreciate it!

Just to let you know that my friend was really impressed with your repair work.

He said that the repair part looks stronger than the rest of the wing.

Thanks again for the rush job. I really appreciate your services.

Much aloha, Doug

Above is the closeup of the finished work. We got a nice letter from the customer about it. He was riding his friend's rig and ended up damaging it. I often wonder if people damage their friends gear with a greater frequency than their own simply because of bad luck.

Below is another wing that was blown open from leading to trailing edge. We are looking at the topside here. This happened during a hard crash on the leading edge causing a shockwave to form which exploited the seam nearest the impact. The ribs were also damaged at the reinforcement points. The second image shows the wing put back together with absolute dimensional accuracy, it's even slightly stronger than it was before.

|

|

|

Below is a Pro-Design Jazz Paraglider

We found this to be a particularly involved repair since the large amount of damage ran just along the seams. We try whenever possible to put the wing back together with minimal deconstruction. We were quite proud of the way these repairs slipped under the existing seams with just a small amount of stitch removal and replacement. Some work still remains to do at the time these shots were taken. Two or three lines need to be replaced. We fabricate lines with absolute accuracy.

|

|

|

Why are we using tripple step zigzag?

It's true, it's not found anywhere else on most paragliders. So why then would we choose to do this? Well, in fact, damage is always a unique situation in the structure. Aside from an area that's damaged, no where else are there two edges that need to be joined together the way ripped edges do. With damage, all of a sudden there are edges that need to meet up perfectly, fiber-for-fiber, edge to edge. A normal seam will not do because a normal seam subtracts any dimension beyond the stitch. When making a wing from the start, it's easy to just build in all of these seam allowances and simply follow the dimension that's been set in the design. Repairs are a different story, they have no seam allowances. Repairs must be done flat, and without any extra cloth being subracted from the wing. Instead we add cloth (usually internally) to bridge the rips. The perimeter of this new cloth gets sewn down and tied into the structure of the wing. The strongest stitch to do flat joining like this is the tripple-step, or running zigzag. We also sew radially around curved corners and avoid over-tacking the terminations of patches by slipping into the same needle holes.

|

|